High-Quality OPGW Suspension Assembly from Trusted Supplier

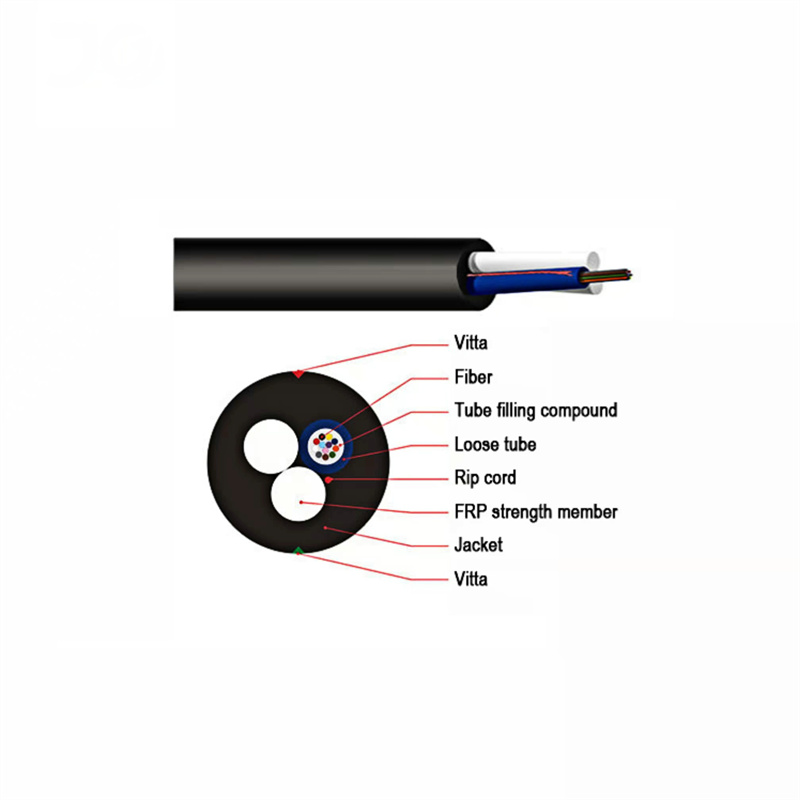

As a reliable choice for your connectivity needs, our OPGW Suspension Assembly is crafted to meet the highest industry standards. I take pride in offering high-quality assemblies that ensure stability and durability in even the most challenging environments. With a focus on performance, this product is designed to maintain optimal tension while supporting overhead ground wires effectively. I understand that finding the right supplier is crucial for your projects, and that's why I strive to provide exceptional customer service alongside our top-notch products. Our OPGW Suspension Assemblies are versatile, making them suitable for various applications, and I’m ready to assist you in selecting the perfect solution for your requirements. Whether you’re expanding your infrastructure or upgrading existing systems, our commitment to quality ensures you’re making a smart investment. Let’s connect and explore how we can support your business needs with the best OPGW Suspension Assemblies available!

Opgw Suspension Assembly Industry Giant Where Innovation Meets 2025

In an increasingly interconnected world, the demand for high-quality OPGW suspension assemblies is experiencing a significant surge. As industries strive for seamless communication and efficient energy transmission, the need for innovative solutions has never been greater. The OPGW suspension assembly stands at the forefront of this transformation, offering robust support and reliability for overhead power lines and telecommunications. What sets apart industry leaders is their commitment to continuous innovation, ensuring that their products not only meet but exceed the evolving standards of performance and safety. The future of the OPGW suspension assembly industry is bright, with advancements in materials and technology paving the way for enhanced durability and efficiency. As we look towards 2025, key developments such as lightweight composites and smart monitoring systems are set to revolutionize how these assemblies function. Global procurement partners can expect not only superior products but also comprehensive support and service that adapt to diverse operational environments. With a focus on sustainability and reducing environmental impact, companies are prioritizing eco-friendly practices while delivering cutting-edge solutions to an ever-growing market. For businesses seeking reliable partners in the OPGW suspension assembly sector, aligning with forward-thinking manufacturers is crucial. By investing in innovative technologies today, procurement professionals can secure a competitive edge for their operations tomorrow. The collaboration between the industry giants and their partners represents a mutual commitment to excellence—one that is poised to drive the future of connectivity and energy distribution across the globe.

Opgw Suspension Assembly Industry Giant Where Innovation Meets 2025

| Innovation Type | Impact on Industry | Emerging Technologies | Market Trends | Sustainability Efforts |

|---|---|---|---|---|

| Smart Sensors | Enhanced monitoring and maintenance | IoT Integration | Increased demand for digital solutions | Use of recyclable materials |

| Advanced Materials | Improved durability and longevity | Nanotechnology | Shift towards lightweight designs | Carbon footprint reduction strategies |

| Automation | Increased efficiency in assembly | Robotics | Growth in automated production lines | Energy-efficient processes |

| Digitalization | Transforming operational efficiency | Big Data Analytics | Trend towards smart factories | Circular economy initiatives |

Related Products