Understanding the Working of Optical Fibre Cable: OEM Suppliers Guide

Understanding the working of optical fibre cable is crucial for anyone in the tech industry today. As an OEM in this field, I’ve seen the impact of high-speed data transmission firsthand. Optical fibres utilize light to transmit data, making them faster and more efficient than traditional copper cables. This technology enables clearer signals over longer distances, reducing the risk of interference. When sourcing from reliable suppliers, I prioritize quality and performance in optical fibre solutions. It’s essential to choose products that meet industry standards to ensure the longevity and reliability of your network. With the right optical fibre cables, businesses can enhance their connectivity and stay ahead in today’s fast-paced digital landscape. If you’re seeking high-quality optical fibre options for your projects, I’m here to help you make informed decisions. Experience the advantages of working with a trusted partner who understands the nuances of optical fibre technology. Let’s optimize your operations together!

Working Of Optical Fibre Cable Products Factory

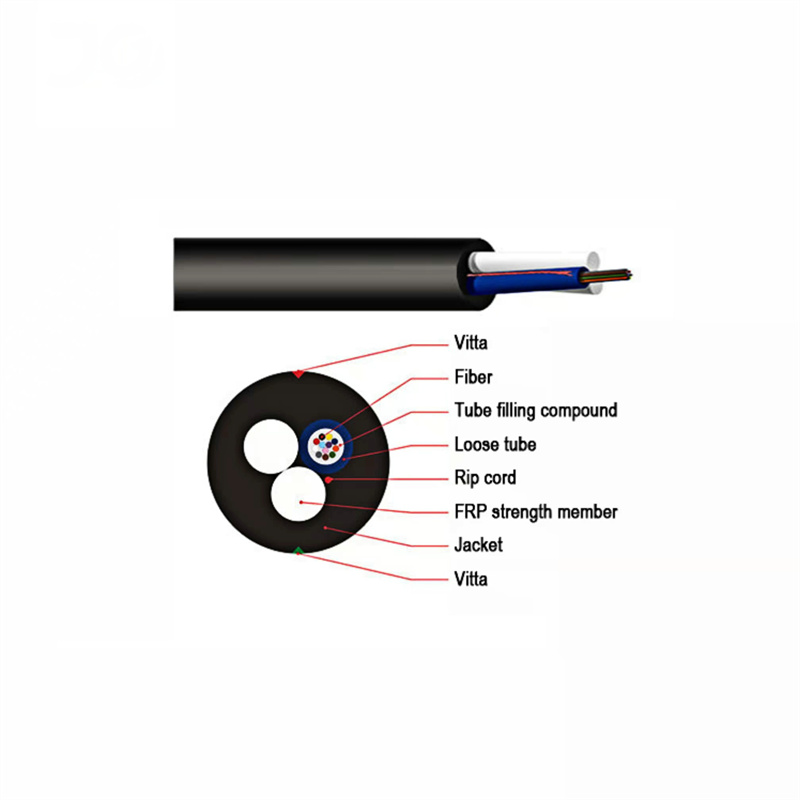

The production process of optical fiber cables is both intricate and fascinating, highlighting the advanced technology employed in modern telecommunications. At the heart of this high-tech manufacturing is a commitment to quality and innovation. Our state-of-the-art factory utilizes cutting-edge machinery and techniques to ensure that each fiber optic cable meets stringent global standards. The process begins with the careful selection of raw materials, including high-purity silica, which is essential for minimizing signal loss and maximizing efficiency. Once the materials are prepared, they undergo a meticulous drawing process where glass fibers are stretched to the desired diameter. These fibers are then coated with protective layers, providing durability and resilience against environmental factors. Quality control mechanisms are in place at every stage to guarantee that the optical fibers maintain optimal performance characteristics. Each finished product is subject to rigorous testing for parameters such as attenuation, tensile strength, and environmental resistance, ensuring that they can withstand the challenges posed by diverse installation environments. Furthermore, the factory operates with sustainability in mind, incorporating eco-friendly practices throughout the production cycle. This includes recycling material waste and utilizing energy-efficient processes to minimize the ecological footprint. As global demand for high-speed internet and reliable telecommunications infrastructure continues to rise, our commitment to quality, sustainability, and innovation positions us as a preferred partner for businesses worldwide looking to enhance their connectivity solutions.

Working Of Optical Fibre Cable Products Factory

| Process Stage | Description | Materials Used | Duration | Quality Control |

|---|---|---|---|---|

| Raw Material Procurement | Sourcing raw materials required for fiber production. | Silica, polymers | 2 weeks | Material quality inspection |

| Fiber Drawing | Drawing the silica into thin fibers. | Glass rods | 1 week | Visual inspection |

| Coating | Applying protective coatings to the fiber. | Polymer coatings | 3 days | Adhesion tests |

| Cabling | Grouping fibers into cables. | Steel, polyethylene | 2 weeks | Strength tests |

| Final Testing | Testing the finished optical fibers for performance. | N/A | 1 week | Performance and reliability tests |

Related Products