High-Quality Fiber Optic Cable Thickness: Expert Supplier Insights

When I'm searching for the best solutions in fiber optic technology, the thickness of fiber optic cable is a crucial factor I consider. A higher quality cable not only ensures optimal performance but also enhances durability and reliability for my projects. I understand that thickness can directly influence signal integrity and transmission speeds, so I always prioritize finding high-quality options. Working with a trusted supplier who understands this is essential. I need to make sure I’m sourcing cables that meet my specifications while also offering competitive pricing. Quality assurance is vital to ensure that the products hold up under pressure. That’s why I’m committed to connecting with suppliers who share my values for quality and service. Whether for a large project or ongoing needs, the thickness of fiber optic cable plays a key role in the success of my networking infrastructure. This is where I know I can find the right balance between quality and reliability.

Thickness Of Fiber Optic Cable Is The Best For the Current Year

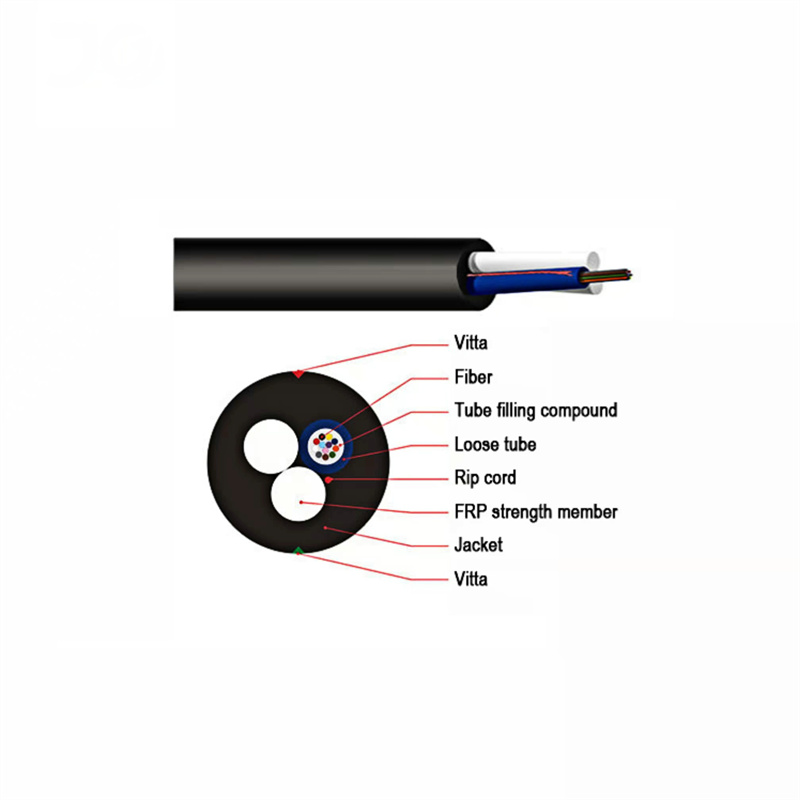

Fiber optic cables are essential for high-speed data transmission, and selecting the right thickness can make a significant difference in performance and reliability. Current trends indicate that the optimal thickness for fiber optic cables is around 250 micron for indoor applications and 900 micron for outdoor environments. This balance ensures sufficient durability while maintaining flexibility for installation in various settings. Thinner cables may be more cost-effective and easier to handle, but they compromise the fiber's ability to withstand environmental challenges. As global demand continues to rise, manufacturers are exploring advanced materials and technologies to enhance fiber optics. Innovations include improved coating materials that offer better abrasion resistance, as well as designs that facilitate easier splicing and connectivity. By adopting these advancements, procurement professionals can ensure that their infrastructure not only meets current demands but is also future-proofed for scalability. In a world where data consumption is ever-increasing, staying updated on the latest specifications and standards for fiber optic cables is crucial for maintaining competitive advantages in networking and communication. Ultimately, the choice of fiber optic cable thickness should align with specific application requirements and environmental conditions. By prioritizing quality and performance, businesses can enhance their network capabilities and prepare for the future of connectivity. Investing in the right fiber optic solutions now will not only address immediate needs but also safeguard against evolving technological demands.

Thickness Of Fiber Optic Cable Is The Best For the Current Year

| Cable Type | Core Diameter (µm) | Outer Diameter (mm) | Material | Applications |

|---|---|---|---|---|

| Single-Mode Fiber | 9 | 125 | Glass | Long Distance Communication |

| Multi-Mode Fiber | 50 | 125 | Glass | Local Area Networks |

| Plastic Optical Fiber | 1.0 | 3.0 | Plastic | Short Distance Communication |

| Ribbon Fiber | 100 | 250 | Glass | High-Density Applications |

Related Products