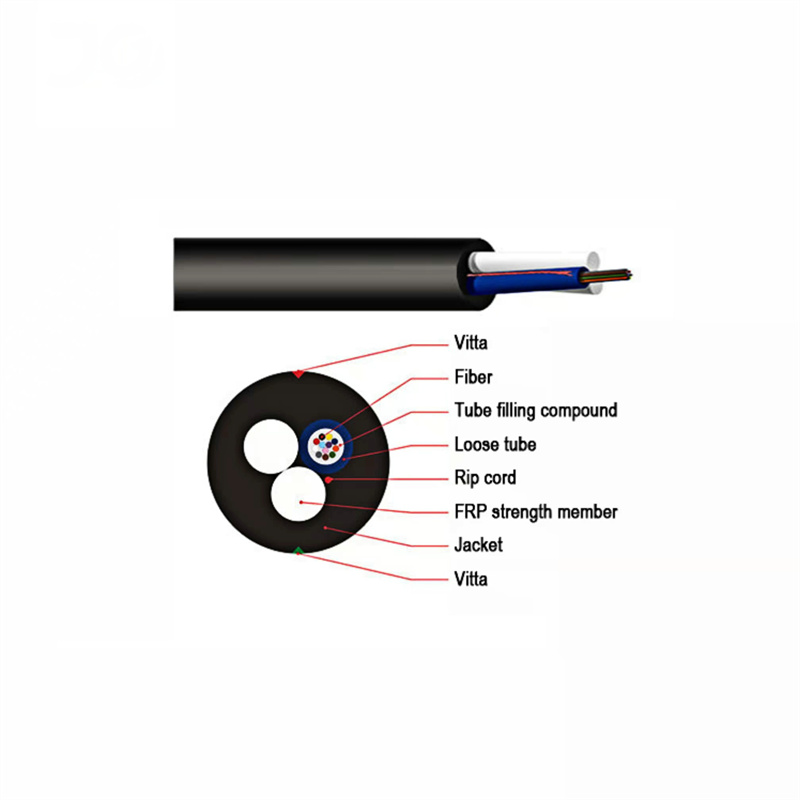

Custom Photoelectric Composite Cable Solutions for Factories

When it comes to enhancing your projects, our Photoelectric Composite Cable offers unmatched versatility and performance. I’ve seen firsthand how it integrates seamlessly into various applications, from industrial automation to smart buildings. What sets our product apart is the option for custom designs, tailored specifically to meet the unique needs of your Factory. Flexibility in specifications means you can optimize the cable's size, length, and shielding for your environment. Built with high-quality materials, this cable boasts superior signal integrity and durability, ensuring that your connections remain reliable even in demanding conditions. I understand how crucial it is for businesses to partner with a supplier that prioritizes quality and responsiveness. That’s why I’m here to help you navigate through the options and find the perfect fit for your requirements. Let's create the ideal solution together, and elevate your operational efficiency with our Photoelectric Composite Cable.

Photoelectric Composite Cable in 2025 Outperforms the Competition

As we look ahead to 2025, the evolution of technology is set to redefine the landscape of the cable industry, particularly with the introduction of advanced photoelectric composite cables. These innovative cables combine the advantages of both optical fiber and traditional copper wiring, making them a game-changer for various applications across sectors like telecommunications, data centers, and industrial automation. Their ability to provide high-speed data transmission while maintaining robust performance in challenging environments positions them as a superior choice for procurement professionals seeking reliability and efficiency. One of the key features that will set photoelectric composite cables apart in 2025 is their unmatched versatility. They are designed to support a wide range of communication protocols and cater to the growing demand for bandwidth in an increasingly connected world. Additionally, their lightweight construction and enhanced durability lead to lower installation costs and reduced maintenance, making them an attractive investment for businesses looking to optimize their operations. With sustainability becoming a central theme in purchase decisions, these cables are crafted to minimize environmental impact while ensuring peak operational efficiency. Moreover, the competition in the cable market will intensify, as more companies recognize the potential of integrating both fiber and copper technologies. However, those who adopt and implement cutting-edge manufacturing techniques will have the upper hand. The continual advancements in materials science will enable improved performance metrics, ensuring that photoelectric composite cables not only meet but exceed the expectations of global purchasers. As the industry progresses towards 2025, staying ahead with these next-generation solutions will be crucial for any organization looking to thrive in a tech-driven marketplace.

Photoelectric Composite Cable Performance Comparison in 2025

| Cable Type | Data Transfer Rate (Gbps) | Signal Loss (dB/km) | Temperature Range (°C) | Flexibility Rating |

|---|---|---|---|---|

| Standard Composite Cable | 10 | 3.5 | -20 to 70 | Moderate |

| Advanced Photoelectric Cable | 25 | 2.0 | -40 to 85 | High |

| Ultra-Flexible Cable | 20 | 2.5 | -30 to 75 | Very High |

| Robust Industrial Cable | 15 | 3.0 | -20 to 80 | Moderate |

Related Products