High-Quality Patchcord FTTH from ODM Factory - Reliable Solutions

When I need reliable connectivity solutions, the Patchcord FTTH is my go-to choice. With its robust design and high-quality materials, this patch cord guarantees optimal performance for fiber-to-the-home installations. I appreciate the versatility it offers, especially when working with different systems. As an ODM, I know how crucial it is to have a partner that understands my specific needs. This factory-manufactured product not only meets industry standards but also allows for customization to fit unique project specifications. Whether I’m aiming for efficiency in a large-scale deployment or looking to streamline my supply chain, these patch cords provide the dependability I count on. Trusting in a factory that prioritizes quality and offers flexibility means I can focus on delivering exceptional service to my clients. The Patchcord FTTH is more than just a product; it's a solution that empowers my business while ensuring seamless connectivity.

Patchcord Ftth Service From Concept to Delivery

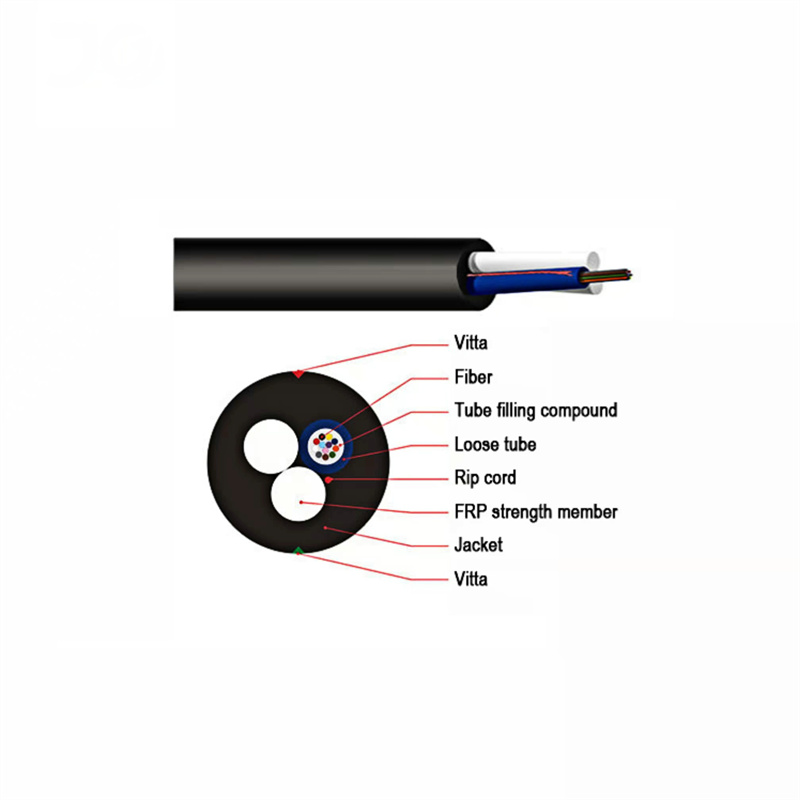

In today's fast-paced digital landscape, the demand for reliable and efficient fiber optic solutions is greater than ever. Offering a robust patchcord FTTH (Fiber to the Home) service is essential for providers looking to enhance connectivity for residential and commercial clients alike. From conceptualization to delivery, a streamlined process ensures that every aspect of the product meets the highest standards of quality and performance. The journey begins with understanding the specific needs of the customer, which involves consulting with them to design tailored patchcord solutions that fit their unique requirements. This collaborative approach allows for flexibility in design and manufacturing, leading to high-quality products that ensure seamless data transmission with minimal loss. Utilizing cutting-edge technology and materials, every patchcord is rigorously tested to guarantee durability and efficiency. Once the design is finalized, the production phase employs advanced manufacturing techniques to create reliable and durable patchcords that can withstand various environmental conditions. A commitment to quality control throughout the manufacturing process enables assurance that every unit delivered is of the finest quality. Efficient logistics systems then ensure timely delivery to customers worldwide, enabling them to meet the growing demands of their own clients and ultimately expand their market reach. This comprehensive approach not only enhances product offerings but also strengthens relationships with global partners, fostering long-term business success.

Patchcord Ftth Service From Concept to Delivery

| Dimension | Description | Example Values |

|---|---|---|

| Connector Type | Type of connector used for fiber patchcords | SC, LC, ST |

| Fiber Mode | The mode of the fiber optic cable | Single Mode, Multi Mode |

| Cable Jacket Material | Material used for the cable jacket | PVC, LSZH |

| Length | Length of the patchcord | 0.5m, 1m, 2m, 3m |

| Application | Typical uses for the patchcords | Indoor, Outdoor, Data Center |

| Termination | Method used for terminating the fiber | Fusion Splicing, Mechanical Splicing |

| Performance Standards | Standards that the patchcords meet | TIA/EIA, ISO/IEC |

Related Products