Opgw Conductor Sizes from Top China Manufacturer: Quality and Options

When it comes to selecting the right OPGW conductor sizes, I understand the importance of finding a reliable solution that meets your project needs. As a seasoned buyer in the industry, I appreciate the benefits of sourcing from a reputable manufacturer in China. Their expertise in producing high-quality OPGW conductors ensures durability and performance, essential for optimal transmission and distribution systems. I'm impressed by the variety of sizes available, allowing us to tailor our requirements for various applications. The innovative design and engineering behind these conductors not only enhance electrical performance but also provide significant resistance against environmental factors. By partnering with a trusted manufacturer, I can ensure that the materials we use are of superior quality, leading to long-term success in our projects. If you're considering OPGW conductors, leveraging a reliable supplier from China could be your key to achieving your operational goals while maintaining safety and efficiency. Let’s connect to discuss how these options can benefit your needs!

Opgw Conductor Sizes Manufacturer Ahead of the Curve

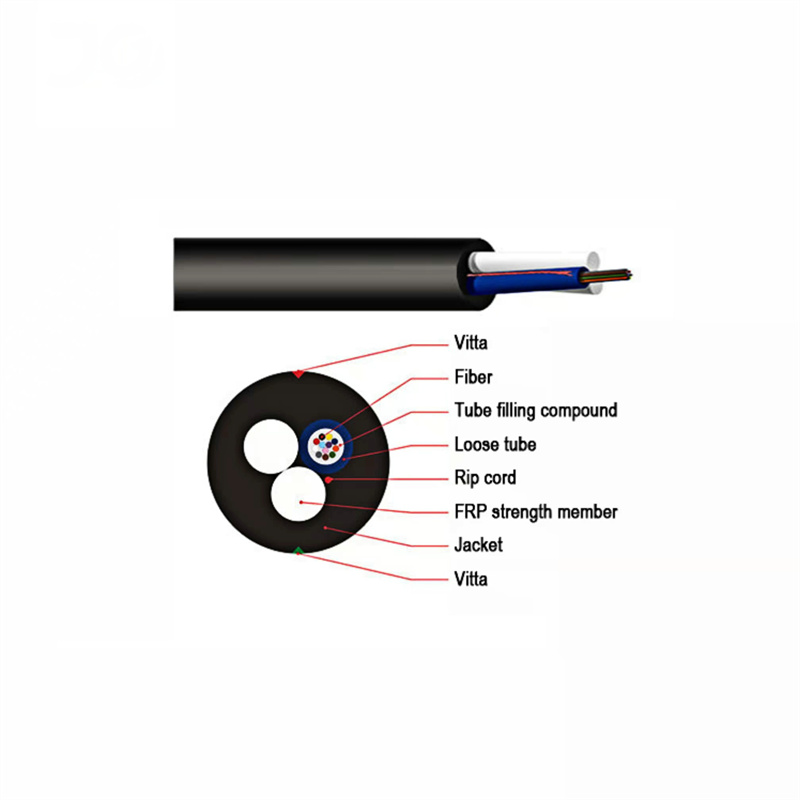

In the ever-evolving telecommunications market, the demand for Optical Ground Wire (OPGW) conductors has surged, driven by the increasing need for reliable and high-speed data transmission. Manufacturers are focusing on advancing their product offerings, providing solutions that meet the diverse needs of global buyers. With a variety of OPGW conductor sizes available, organizations can select the most suitable option that aligns with their infrastructure requirements while ensuring optimal performance and safety. As a leader in the OPGW manufacturing sector, companies are committed to utilizing cutting-edge technology and rigorous quality control processes to deliver products that exceed industry standards. The flexibility in conductor sizes allows for customization, enabling clients to tailor solutions that fit specific scenarios, whether for new installations or upgrades to existing systems. By choosing the right OPGW size, purchasers ensure enhanced connectivity and reduced signal loss, ultimately leading to improved network reliability. In addition to size variability, manufacturers are also embracing innovative advancements in materials and design to enhance durability and efficiency. This positions them at the forefront of the industry, ready to meet the growing demands of the global market while ensuring customer satisfaction. As procurement professionals seek reliable partners, the importance of a manufacturer that understands technical nuances and logistical challenges cannot be overstated. Investing in high-quality OPGW solutions is essential for forward-thinking organizations aiming to stay ahead in the competitive telecommunications landscape.

OPGW Conductor Sizes Manufacturer Ahead of the Curve

| Conductor Size (mm²) | Outer Diameter (mm) | Weight (kg/km) | Max Current (A) | Material |

|---|---|---|---|---|

| 50 | 12.0 | 200 | 90 | Aluminum |

| 100 | 14.5 | 350 | 140 | Aluminum |

| 150 | 16.0 | 480 | 200 | Aluminum |

| 200 | 18.0 | 600 | 260 | Aluminum |

| 250 | 20.0 | 750 | 300 | Aluminum |

Related Products